Recent research backs up what we already know from practice: construction work is suboptimal. What happens on a construction site has not kept up with the demands of an increasingly complex work environment. Situational awareness could give on-site employees the necessary means to finally reap the productivity benefits of digitalization.

Under the

guidance of Professor Olli Seppänen, research teams at the Finnish Aalto

University have delved into everyday conditions at a construction site. With

the workers’ permission, they used video cameras, sensors, and surveys to locate

the bottlenecks in productivity. The researchers also monitored the movement of

products and materials on a construction site. The results are eye-opening.

According

to Aalto’s data, digitalization has not improved the productivity of

construction foremen and workers. A typical worker still spends up to 70% of

their time on activities that add no value: searching for information, unnecessary

movement, and waiting. Construction materials are moved from place to place six

times on the site before being consumed. In addition, especially on large

construction sites, machinery often goes missing or is displaced.

Better Work Planning

Improves Productivity

Two reasons

for these inefficiencies stand out: improper planning, and the lack of

information for the successful completion of a specific task. Tackling these

two issues provides considerable productivity improvements.

An Aalto graduate, Hans

Pasila, positioned video cameras on workers’ hardhats in order to analyze

drywall installation processes. He noticed how the installation team had to

move about a lot in order to fetch missing information, tools, and materials. He

then created a bill of materials for each room, which enabled the delivery of

the right amount of materials to each room. This, and a few other small changes

in the process, resulted in a 20% reduction in movement and a 10% increase in overall

team productivity.

Professor

Seppänen emphasizes that the planning of work should be more detailed. It

should also incorporate industrial production and logistics processes, as

Suffolk Construction has demonstrated in the USA. On one large project, they spent

10,000 extra hours in planning, which improved installation productivity and led

to a 20% increase in the general contractor’s profits and a seven-figure cost

saving for the owner.

Situational Awareness

For any construction

project, we already have a huge amount of data. Designers create building

information models (BIMs), estimators provide material takeoffs, project

managers create documents and schedules, inspectors collect information,

manufacturers have their own production data, and so on. IoT sensors, cameras,

and drones will multiply the amount of project data in the coming years. The

problem is that those working on a site still lack information that is

collected and presented in a way that supports the tasks they must carry out.

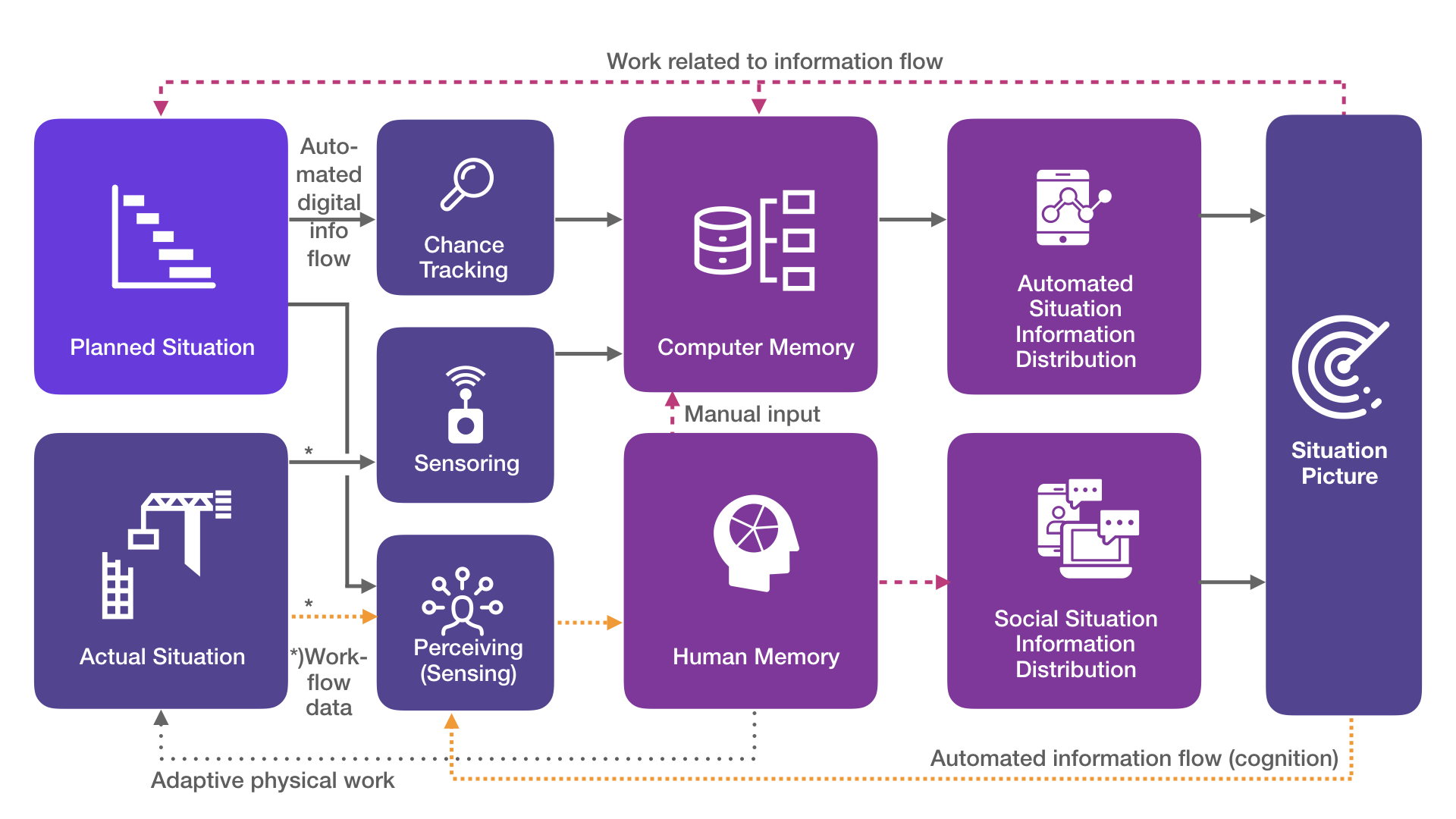

What foremen and workers need is called situational awareness, a situation picture (see Figure 1). It means that every project participant gets the information they need about the project’s past, present, and future status.

The

installation of a façade panel illustrates how situational awareness could work.

The installation supervisor receives information on which panels are to be

installed, when those panels will arrive on site, where they must be installed,

and in what sequence. The installation worker and the crane operator see the

exact location of the panel in the building façade on their devices. When the

panel is in place, the supervisor receives an automated update that the job has

been completed.

Likewise, as

the building is being erected, there are hundreds of indoor spaces that are in

constant states of change. Situational awareness provides the means to know

exactly what to do, where and when, and shows if the work is proceeding as

planned.

Figure 1. A conceptual model of situational awareness/situation picture. Adapted from a paper Situation Picture Through Construction Information Management by Risto Kärkkäinen, Rita Lavikka, Olli Seppänen and Antti Peltokorpi (2019)

Digitalization Enables

Situational Awareness

To fully

implement situational awareness, you need data from the construction schedule,

BIMs, manufacturers’ ERP systems, the transport companies’ logistics systems,

and the construction site sensor network. This is possible only if the data flows across

partners and processes and is interoperable. In today’s world, that’s not an

easy task. To address this challenge, Aalto University’s Digitalizing

Construction (DiCtion) project has devised a shared data model, an ontology, of

the construction process. It is a work in progress, but if implemented, it will

bring situational awareness one step closer to realization.

Situational

awareness is not just about making data accessible to people and machines. It’s

also about making data usable. Designing the user experience so that workers in

harsh environments can locate information and then act on it is a demanding

task.

The

digitalization of processes and situational awareness point to a future where

construction becomes more like manufacturing. The sheer volume of new

construction required necessitates this transformation. The growing demands for

life-cycle thinking from building owners also put pressure on achieving

data-driven and better controlled processes.

The transformation is possible, but it calls for increased collaboration between businesses, researchers, and tech developers. The Finnish construction industry’s efforts in the Aalto University-led Building 2030 consortium and in several joint R&D projects serve as a good example for others to follow.