I know what you’re thinking, here we go again, another blog proclaiming another lean construction technique to be “the best ever”. Fear not for we at cnstrctr are generally skeptical when it comes to new methods to time proven ways of doing things.

So let’s start with something simple – what is lean construction?

Lean construction is one of those buzz words going around the industry right now. Lean Construction means reducing the number of steps and procedures in place either through collaboration, automation or refining. This isn’t a new concept but it’s picked up a lot of steam in the last few years.

We won’t go into a lot of detail surrounding other lean construction techniques, but, if your’re interested there’s a blog all about lean construction you can check out.

How Does Pull Planning Fit Into It?

Pull planning is considered a lean scheduling technique. We’ll go into what it is in a bit but all you need to know for now is that it makes scheduling weekly and daily tasks easier through collaboration.

Okay Great – What Is Pull Planning?

Pull planning is given away by it’s name. Planning by pulling. Essentially rather then starting at the beginning as you would most schedules you start at the end (with an already pre-established milestone) and work backwards.

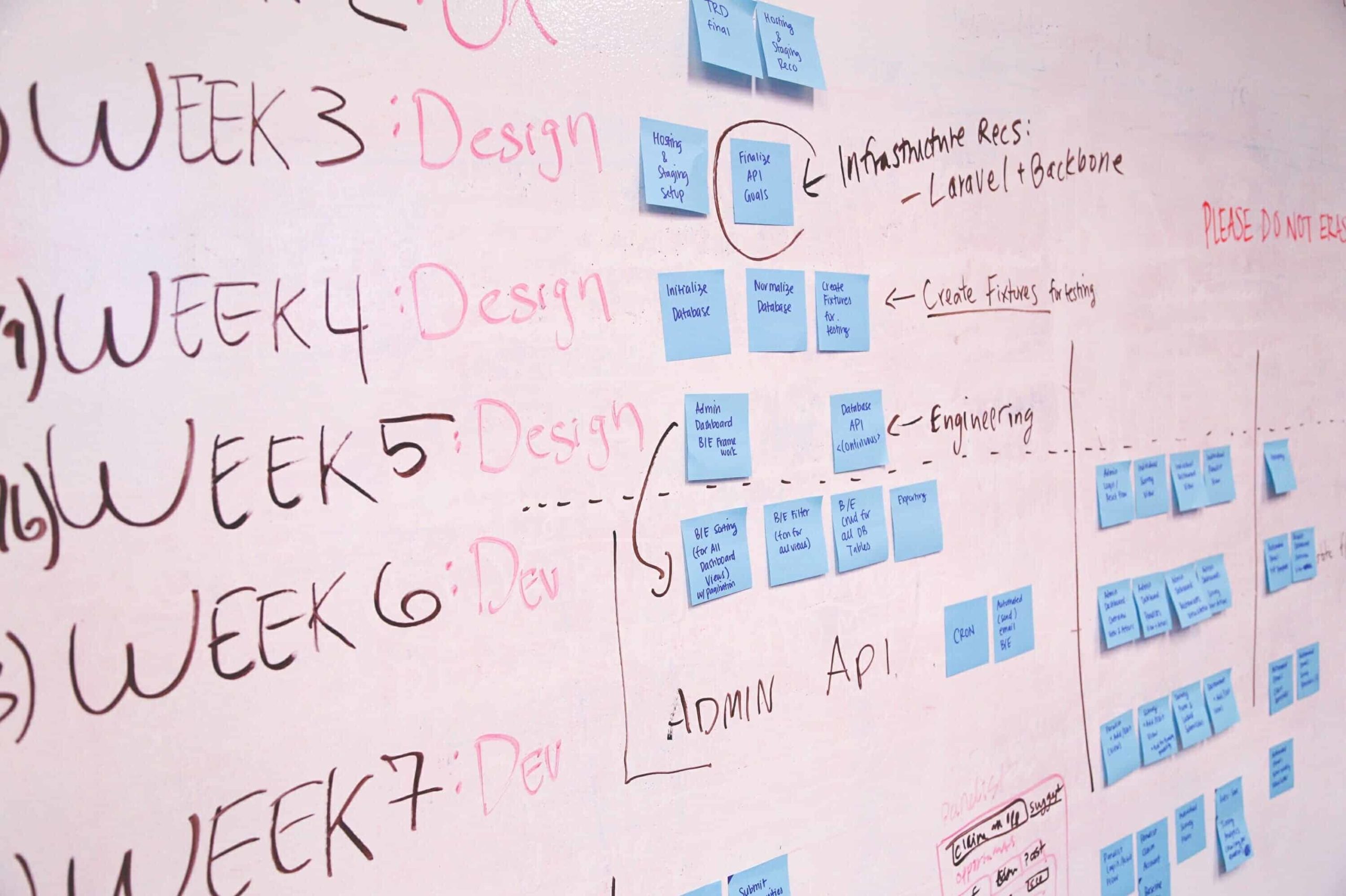

Pull Planning can be done without the use of special systems but, someone has patented the idea and you’ll often hear the “Last Planner System” mentioned. The Last Planner System is an exercise using sticky notes to represent activities and it’s what we will be discussing today.

The Last Planner System (aka Pull Planning) brings all of the people you need into a room (ie foremen, project managers, etc) and let’s them contribute to the schedule. It begins by posting a milestone (ie project completion) and working backwards. Each trade is responsible for posting their own activities with their own coloured sticky note in the sequence.

So for example if the milestone was project completion the sticky note before it might be finished paint, and the sticky note before it might be finish taping.

Each week you review the progress that was made and remove stickies that were completed. The week ahead is then reviewed, new stickies added or reconfigured as needed.

So What Do I Need to Get Started?

There are a lot of little miniscule details that you could get bogged down with in this system but the overall concept is very easy to get started with. Your first step should be getting your foremen together on a weekly basis. The next step will be finding a wall, drawing some lines on it in a grid and buying some coloured stickies. After that the exercise is straight foward (as explained above).

There are kits and special stickies you can buy but that is over complicating the process.

The intention of the Pull Planning process is to get people communicating. So if the painter needs to paint walls he needs to be clear on what he needs. If that means having the drywaller finish tape the walls instead of just drywalling them, it can be discussed in the meeting rather then find out two weeks later.

Great – I’ve Got the Concept Figured Out, What’s In the Pull Planning Details?

The details are where the Last Planner System really stands out (and may over complicate it a bit). There are a number of other key items to do when performing this exercise, we’ve summarized a few of them below:

Phase Planning and Weekly Planning – on larger projects it may be necessary to have a larger session where you focus on the phase instead of the weeks ahead. This will allow you to generate a “big picture plan” and that will be followed weekly by the regular planning sessions.

Manpower, Constraints, Etc – the kits come with constraints, manpower counts and other details listed on the stickies. These are there to help trades understand where there crews are and their overall manpower requirements. The constaints allows trades to list items they need to complete their task.

Measurement – Each week the pull planning boards are updated and a percentage is taken to see how many dates were actually hit. If a trade finishes an activity ahead or behind schedule it means the activity was missed. This incentivizes people to start being open and honest about their work.

Issues – Issues are listed each week and that way management can track them and ensure they get resolved.

This Is All Really Good Information About Pull Planning – But What Does It Improve?

People that are really into the whole lean and process improvement will rhyme of a number of statistics at this point. The honest truth about pull planning is that it improves a few things:

- Communication is improved by each trade being responsible for their own activities and timelines. People are responsible for identifying their own activities as well as those of others so more discussion happens up front.

- Scheduling Accuracy – because people are encouraged to be more open about their work and the durations you won’t have activities slipping forward or backward each week.

Pull Planning utilizing the Last Planner System isn’t intended to reinvent the wheel and won’t cut time off of your project schedule but it will help you in developing your weekly plans.

Have you implemented Pull Planning on your construction project? If so let us know in the comments below!